Model Deformation Measurement

Despite wind tunnel models being manufactured from high-grade metals and capable of withstanding high aerodynamic loads, it cannot be assumed that the geometry is inflexible.

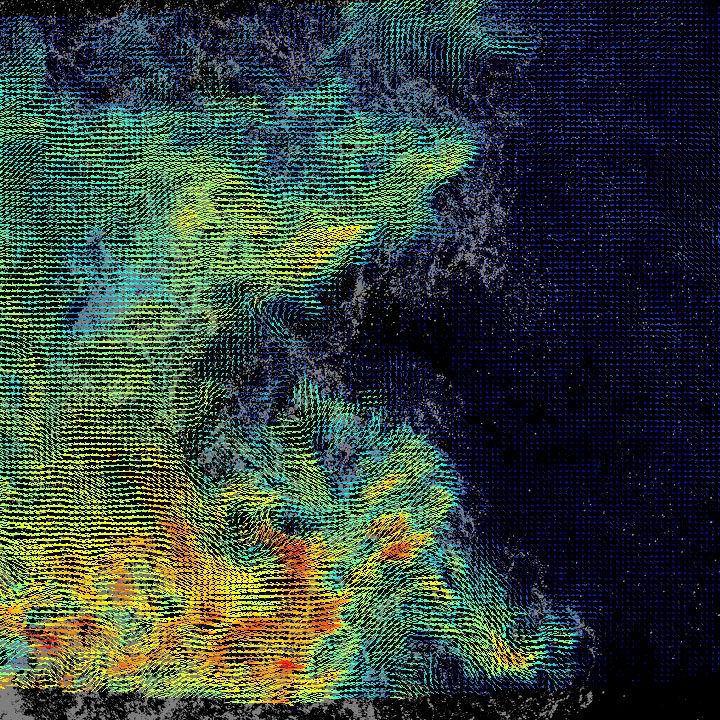

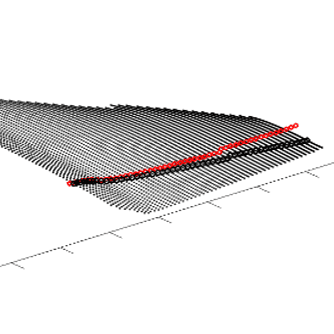

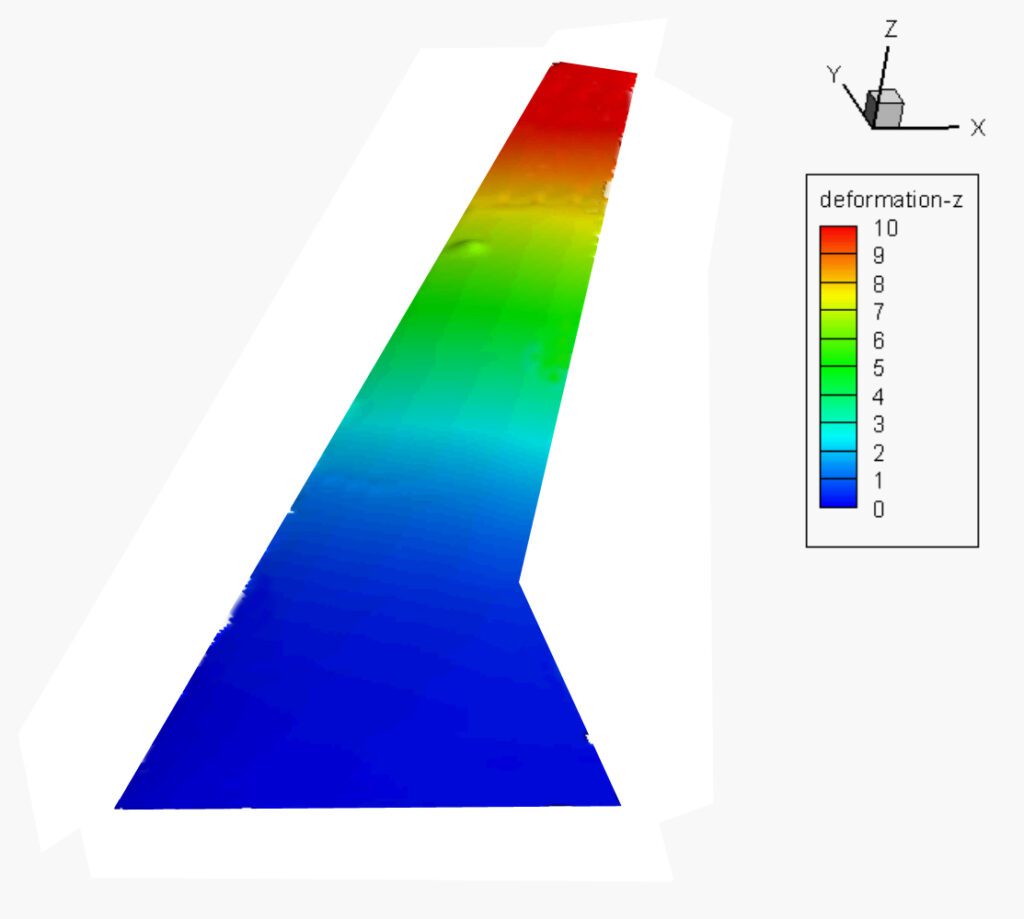

Wings are known to bend and twist under high aerodynamic load, which is effectively changing the geometry being tested. Therefore, it is desirable to be able to measure these deformations and the most effective way to perform these spatial measurements is using optical systems using techniques such as digital image correlation.

ARA has developed a Model Deformation Measurement (MDM) system capable of measuring large and small changes in model shape at a variety of test conditions. This is based on the ARA PIV system hardware and software. This helps to ensure that the model is accurately representing the full-scale aircraft and to make sure that the geometry is fully known to allow meaningful comparison with CFD solutions. MDM will become an even more important tool as aero-elastic models become a regular requirement for test.

The ARA MDM system has since been extended to include the high speed cameras to enable Model Deformation Measurements for dynamic load conditions. This enables frequency analysis of the model movement to be performed.